Keywords:

Automated Machine Technologies, Inc. is a manufacturer of aseptic liquid filling and capping machines, plugging, crimping, sterile vial stoppering monoblock machine, e-cigarettes automatic cartomizer filling machine, inline liquid filler, plugger, crimper capper machinery and equipment, sterile vial monoblocks, fillers, pluggers and cappers for pharmaceutical, cosmetic and food packaging. e-Cigarettes cartomizers filling VG PG glycol solutions, Micro-Liter dispensing filling and verification of 96-well and 384-well Microplate Dispenser with digitally compensated servo controlled peristaltic pump and automatic verification, P&A Labeling.

|

|

|

|

|

|

|

|

AMT™ Servo Monoblock

From 0.1 ml to 1000 ml total ServoChange™ in less than 10 minutes!

DOWNLOAD Servo Monoblock video

DOWNLOAD eCig Monoblock video

DOWNLOAD Monoblock Brochure PDF (0.3MB)

Liquid Filling and Closing Monoblock is ideal for precise and sterile productions,

especially where frequent immediate changeover to many different products is required.

The AMT™ Monoblock machine has a very small footprint and will outperform functions that

normally require employment of many separate machines. Fill volumes from a fraction of 1 ml to 1 liter and production speeds up to 80 bottles per minute are achievable depending on the product. Many nozzle configurations are available depending on volume and production speed requirements. The AMT™ Servo Monoblock will accept containers of various shapes and sizes with a minimal number of change parts. Fill precision can be better than 0.2%, depending on the product, production speeds, and

pump used (see Sterile Liquid Filling below).

Effectively crafted, modular design allows

for immediate changeover to different functions, various product sizes and shapes.

Production parameters and records are kept in the computer for immediate changeover, reports generation and

easy validation, and are available with a touch of the screen. Components such as motors and belts

are isolated below the fill area, providing assurance against particulate contamination.

Monoblock can be equipped with its own conveyor or it can operate from the customer's conveyor.

Sterile Liquid Filling

Monoblock will accept various dispensing systems upon client preference.

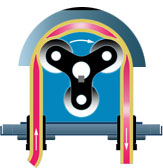

AMT™ Servo Peristaltic Pump

The servo controlled, digitally compensated AMT™ Peristaltic Micro Pump is freed from the alleged precision shortcomings of peristaltic pumps by digitizing and compensating the flow characteristic (US Patent Number 6,393,338). As disclosed in the Patent, the servo-driver varies the rotary stroke accordingly based on a digitized flow characteristic. The long term tubing wear is also computed for automatic compensation. This technique allows for achieving the highest dispensing precision, while maintaining all the benefits associated with using rotary peristaltic pumps, especially unlimited programmable fill volumes and sterile operation with minimal maintenance. The benefits of using AMT™ Digitally Compensated Peristaltic Pumps greatly outweigh those of ceramic piston or syringe pumps.Better than 0.2% fill precision is achievable. Volume calibration is immediate from the touch screen and can be performed without stopping production. AMT™ servo pumps have programmable speed and acceleration for optimum performance. Drip-less operation is obtained via the SuckBack system. Reversible flow and jogging are provided for system purging and priming. The pumps are suitable for CIP (Cleaning In Place). Tubing and bottom up nozzles are the only fluid contact parts. They can be disposable or disassembled in a few minutes for sterilization and reassembled with reduced risk for contamination.

- From fraction of 1ml to 1 liter programmable fill volumes

- Fill accuracy can be better than 0.2% based on product and speed

- Up to 120 fills per minute production

- 100 programs for immediate changeover

- Suck back system for drip-less production

- Jog forward and reverse functions for priming and purging

AMT™ Servo Piston Pump

The servo controller performs S-curve motion for smooth dispensing. Volume calibration is immediate from the touch screen and can be performed without stopping production. Jog forward and reverse functions are for priming and purging. Optional SuckBack is provided by intake valve. Parameters like volume, acceleration and speed are programmable. A number of standard, disposable and sanitary piston pumps can be used with the AMT™ system. DUS filling unit features a rolling diaphragm that isolates the piston head from the cylinder wall. Vacuum assistance applied to the underside of the diaphragm maintains the proper convulsion. Three types of valves are available: ball check, duck bill or pinch valve.

- From 1mm to 100cm programmable strokes

- From fraction of 1ml to 1 liter programmable fill volumes

- Fill accuracy can be better than 0.25% depending on product and speed

- Up to 180 fills per minute production

- 100 programs for immediate changeover to different products and pistons

- Suck back system for drip-less production

- Jog forward and reverse functions for priming and purging

Two precision load cells measure tare and gross weights for each production cycle. 100% weigh checking and SPC provide immediate feedback to servo pump for maintaining highest fill precision. Custom reports are generated.

Stoppering Plugging

Stoppering Plugging

Automatic stoppering is performed with full or partial insertion. AMT™ Monoblock can automatically insert various sizes and shapes of stoppers, plugs, and orifices into the container.

Screw CappingServoTorque™ - patented servo capping along with flexible positive gripping system, brings unparalleled torque precision and consistency in chuck screw capping. (US Patent Number 6,804,929).

Crimp SealingAluminum closure crimp sealing device is easily exchangeable with screw capping chuck.

Orienting and Feeding

Orienting and Feeding

Vibratory bowls orient and supply stoppers, plugs, orifices, screw caps, aluminum crimp closures. Only a few change parts are used for a wide range of product sizes and shapes. The hopper bowls and tooling are made of 316 stainless steel and are easily removable for sterilization. Servo drivers automatically readjust vibratory bowls for pre-programmed bottle height.

Servo ChangeoverModular exchangeability and the uniquely programmable ServoChange™ dramatically reduces set up time and makes validation easy. Parameters and functions are computer recorded in pre-programmed production profiles. A desired product profile is called up with a touch of the screen for new production or for editing. A practically unlimited number of product profiles can be stored for immediate recall.

Rotary bottle indexing star-wheels have quick disconnects and are easily exchanged. The star-wheel servo driver has programmable acceleration for optimum performance. The capping chuck is easily exchangeable with a crimp sealing device. Servo drivers automatically readjust the AMT™ monoblock and vibratory bowls for pre-programmed bottle heights. Nozzle top and bottom positions, fill volumes, calibration, speeds, accelerations, timing and other parameters are also automatically set by software.

|

|

|

|

(Acrobat Reader needed.)

If you wish to download free Acrobat Reader, click Adobe logo:

Contact us for peristaltic liquid filling and capping, stoppering, P&A labeling production machines:

Office@AMTLiquidFilling.com (919) 361 0121

|

|

|

|

|

|

|

|

Servo Monoblock - Multifunctional Machine

Copyright™ 2025

Automated Machine Technologies, Inc.

8421 Burnett Rd, Dunn NC 28334

Email: Office@AMTLiquidFilling.com Phone: (919) 361 0121